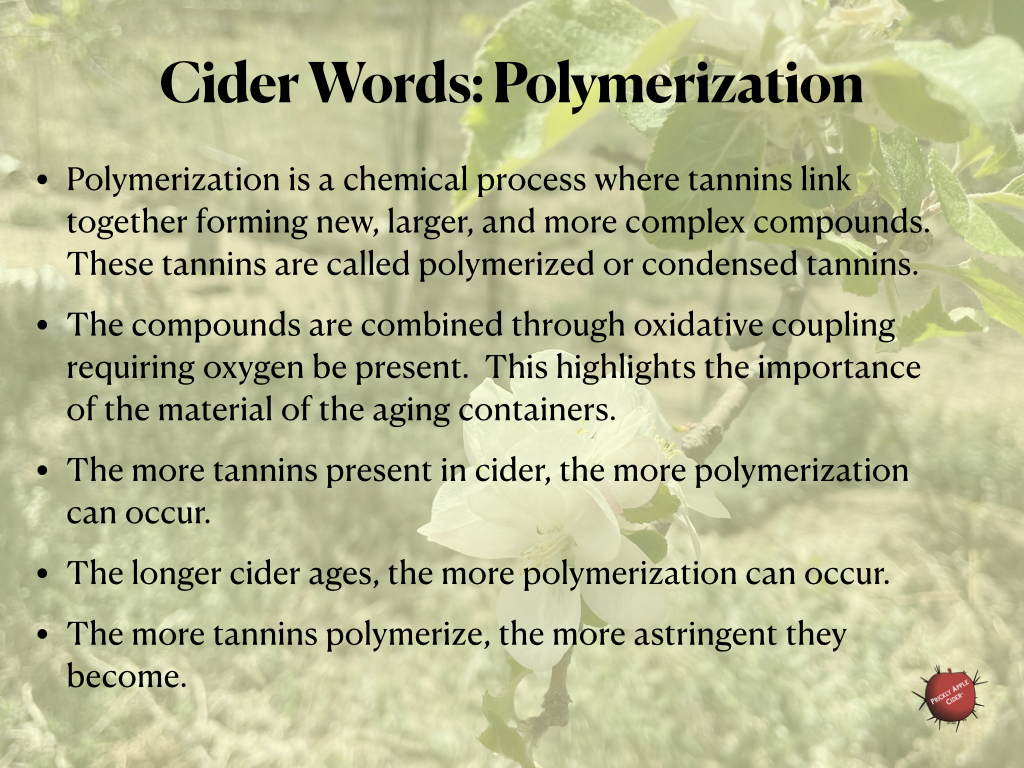

Polymerization can be a key part of the aging process for cider. It is a chemical process in which the tannins found in the cider combine to form larger and more complex molecules. This process is enabled by oxygen through oxidative coupling. Tannins are found at higher concentrations in apples known as bitters, but the highest concentration of tannins is found at high in the apple’s peel and core (around the seeds). Tannins are responsible for the astringency of cider, as well as contributing to its color, flavor, aroma, and bitterness. The polymerization process begins once fermentation ends. The process can last anywhere from a few months to several years, but requires continued access to at least micro levels of oxygen. This is where the container you select for aging can have an impact. Barrels, bottles with corks, and plastic can allow small amounts of oxygen to enter the cider while glass and stainless don’t. Both time and the container have a significant impact on the flavor and aroma of the finished cider. Generally, the longer the aging, the more polymerization happens.

The chemistry of cider polymerization is complex, but it involves a series of reactions between tannins and various other molecules found in the cider. These compounds go through an oxidative coupling process forming new larger and more complex compounds. Generally, the more tannins polymerize, the more astringent they become. Two key factors that can influence the polymerization of tannins in cider is the variety of apples used and the inclusion of the peels. Macerating your pomace or even adding peels directly to the fermenter will also increase the amount of tannins in your cider since it will pull more the peels. Other factors can influence cider polymerization to varying degrees. These include temperature, humidity, and oxygen exposure during the aging process. Cider makers carefully manage these factors to achieve the desired level of polymerization and create a cider with the desired flavor and aroma profile.

The benefits of cider polymerization are numerous. It can enhance the overall flavor and aroma of the cider, and can also increase its stability and shelf life. Ciders that are properly aged and polymerized can have a more complex and nuanced flavor profile, with notes of fruit, spice, and earthiness. As with everything involving cider making, there are also risks associated with cider polymerization. If the cider is over-polymerized, it can become too astringent and harsh, with a bitter or medicinal taste. This can be avoided by carefully controlling the aging process, and by choosing apples and peels with the desired tannin profile.

Do you want to know more about cider-making process? Checkout some additional articles below.

Don’t miss any future Mālus Trivium articles. Follow me and you will get a link to my latest article delivered to your inbox. It’s that easy!